A sub-site of the Onondaga Lake Superfund Site

Partial List of site Contaminants

| CAS # | Contaminant Name | Contaminated Media |

More Information |

| TRICHLOROBENZENE | http://www.cdc.gov | ||

| 71-43-2 | BENZENE | ATSDR Profile | |

| 108-90-7 | CHLOROBENZENE | ATSDR Profile | |

| DICHLOROBENZENE | ToxFAQs | ||

| DIOXIN | Policy | ||

| 7439-97-6 | MERCURY | ATSDR Profile | |

| 91-20-3, 00090-12-0 | NAPHTHALENE | ATSDR Profile | |

| ORTHO-DICHLOROBENZENE | ToxFAQs | ||

| 108-88-3 | TOLUENE | ATSDR Profile | |

| 1330-20-7 | XYLENE (MIXED) | ToxFAQs |

Summary of Project Completion Dates

| Project Name | Completion Date |

|---|---|

| Remedial Action | 04/01/1991 |

| Project Name | Completion Date |

|---|---|

| Remedial Design | 12/01/1992 |

| Remedial Action | 06/01/1993 |

| Project Name | Completion Date |

|---|---|

| Remedial Design | 11/01/1995 |

| Remedial Action | 03/01/1996 |

| Project Name | Completion Date |

|---|---|

| Remedial Design | 11/01/1996 |

| Remedial Action | 06/01/1997 |

| Project Name | Completion Date |

|---|---|

| Remedial Action | 08/01/1999 |

| Project Name | Completion Date |

|---|---|

| Remedial Design | 10/12/2006 |

| Remedial Action | 06/11/2008 |

| Project Name | Completion Date |

|---|---|

| Remedial Design | 04/16/2002 |

| Remedial Action | 05/01/2003 |

| Project Name | Completion Date |

|---|---|

| Remedial Design | 11/06/2002 |

| Project Name | Completion Date |

|---|---|

| Remedial Design | 10/15/2001 |

| Remedial Action | 03/19/2003 |

| Project Name | Completion Date |

|---|---|

| Remedial Design | 09/30/2005 |

| Remedial Action | 03/24/2006 |

History of the Solvay process

The Solvay process, also referred to as the ammonia-soda process, is the major industrial process for the production of soda ash (sodium carbonate). The ammonia-soda process was developed into its modern form by Ernest Solvay during the 1860s. The ingredients for this process are readily available and inexpensive: salt brine (from inland sources or from the sea) and limestone (from mines). The worldwide production of soda ash in 2005 has been estimated at 42 billion kilograms (92 billion pounds),which is more than six kilograms per year for each person on earth. Solvay-based chemical plants now produce roughly three-fourths of this supply, with the remainder being mined from natural deposits.

Byproducts and Wastes

The principal byproduct of the Solvay process is calcium chloride (CaCl2) in aqueous solution. The process has other waste and byproducts as well. Not all of the limestone that is calcined is converted to quicklime and carbon dioxide (in reaction II); the residual calcium carbonate and other components of the limestone becomes wastes. In addition, the salt brine used by the process is usually purified to remove magnesium and calcium ions, typically to form carbonates; otherwise, these impurities would lead to scale in the various reaction vessels and towers. These carbonates are additional waste products.

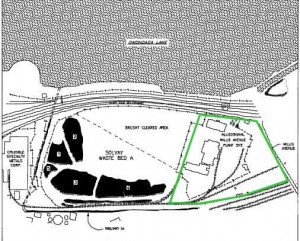

In inland plants, such as that in Solvay, New York, the byproducts have been deposited in “waste beds;” the weight of material deposited in these waste beds exceeded that of the soda ash produced by about 50%. These waste beds have led to water pollution, principally by calcium and chlorine ions. The waste beds in Solvay, New York substantially increased the salinity in nearby Onondaga Lake, which is among the most polluted lakes in the U.S. and is a superfund pollution site. As such waste beds age, they do begin to support plant communities which have been the subject of several scientific studies.

Honeywell agrees to spend $451 million to clean up N.Y. lake

Posted 10/12/2006

Honeywell (HON) will spend $451 million to help clean up Onondaga Lake, once a sacred American Indian waterway turned into a toxic stew by a century of municipal and industrial pollution.

The agreement announced Thursday is one of the largest legal settlements against a polluter in state history, said Gov. George Pataki and Attorney General Eliot Spitzer.

Honeywell will commit to a nine-year cleanup plan that calls for dredging 2.65 million cubic yards of contaminated sediment from the five-mile long lake on Syracuse’s northeastern limits, according to a consent order to be filed in U.S. District Court in Syracuse.

Additionally, Honeywell, based in Morris Township, N.J., agreed to seal 579 acres of lake bottom with a cap of sand, gravel and other material.

Meanwhile, Onondaga County is spending $500 million on a 15-year project to stop polluting the lake with sewage by 2012. The county is under a federal court order to make the lake safe for swimming and fishing and comply with the federal Clean Water Act.

Much of the lake’s contamination is the legacy of a former Allied Chemical complex that closed in 1986, leaving behind mercury and other contaminants. Honeywell took over Allied in 1999 and became responsible for the pollution. Municipal sewage overflows have also fouled the lake.

Onondaga Lake was once the spiritual center of the Onondaga Nation, one of the six upstate New York tribes that formed the Iroquois Confederacy. The great Onondaga Chief Hiawatha once canoed on its waters. In the late 19th century, the lake was ringed by grand resorts and amusement parks and was a popular sports fishery.

Today, it is one of only three lakes in the country listed as a federal Superfund site. Copyright 2006 The Associated Press.